| |

| Heat and Electric Power

Solutions |

| |

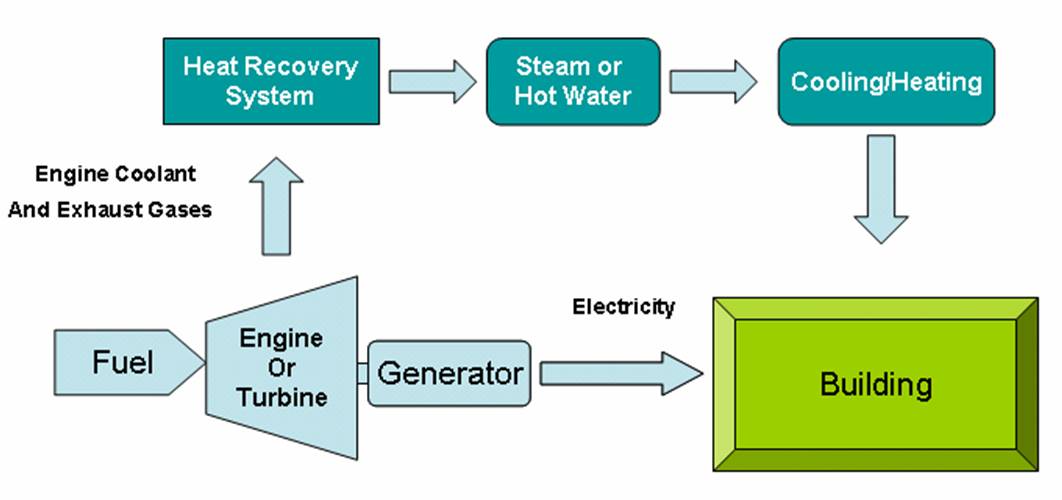

| Combined

Heat and Power (CHP)

systems use an engine-generator

(located on-site or near-site)

to produce electricity

and heat from a single fuel source.

Heat that

would

otherwise

be

wasted is recovered and used for producing steam,

hot water, heating buildings, or industrial process

heat.

|

•

•

|

| |

|

To compete with electricity from the grid, a

CHP

system

must be highly efficient. CHP

systems

can achieve

efficiencies of the order of 85%, resulting in tremendous energy savings.

They

often pay for themselves in 2 to 4 years.

Further, if you

already own suitable standby

engine-generator(s), it can be readily incorporated in a CHP

system. One of the most attractive aspects of CHP is its

ability to offset demand charges. Demand charges are based

on the peak amount of energy that a facility uses. By running a CHP system

during peak periods, a facility can lower its demand charge

significantly. |

| |

| Electricity is provided

using one or more power generation

options, including internal

combustion engines, combustion

turbines, Microturbines,

steam turbines, or Fuel cells. The

power generation equipment may be

fired by natural gas, diesel, propane, or other

fuels. |

| |

| We design,

integrate, install, and sell systems/equipment for combined

heat

and power generation. We do not represent a single

manufacturer. We help our clients

select the best equipment for their application. Our goal is

to develop systems with the highest energy conversion

efficiency, reliability, and the return on investment. |

| |

|

Applications |

|

|

-

Hospitals

-

Dry Cleaners

- Hotels,

Restaurants

- Schools,

Colleges, Universities

- Sports and

fitness centers

|

|

| |

|

|

| |

|

|

|

Cummings Lean–Burn natural gas

generator, 315kW to 2 MW, provides high fuel

efficiency and very low emissions. Ideal for peaking, prime

power and CHP. |

| |

|

|

Ingersol-Rand 250 kW

microturbines. Use for continuous electric power. Unit

incorporates high quality, clean exhaust for use in

cogeneration. Indoor or outdoor operation. |

|